Auburn University hosts first cross-laminated timber conference in southern U.S.

Article body

The Auburn University College of Forestry, Wildlife and Environment, in partnership with several other academic colleges and administrative offices, recently hosted the first cross-laminated timber, or CLT, conference in the southern United States at The Hotel at Auburn University and Dixon Conference Center.

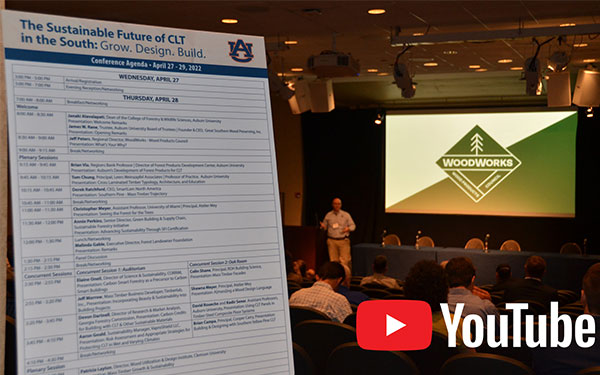

The three-day event, titled “The Sustainable Future of CLT in the South: Grow. Design. Build.,” was held April 27-29, with over 160 attendees participating from across the country, including Texas, Georgia, Florida, Alabama and other states in the southern U.S. The conference featured renowned experts in forestry, building sciences, engineering and architecture and design who shared the latest CLT research, trends and developments in the South.

CLT is a prefabricated wood panel made from wood stacked and glued crosswise in alternating directions to create pressed layers. This unique engineering gives the panel exceptional strength and strong fire protection while remaining lighter and creating less waste during installation than conventional alternatives, such as concrete and steel.

With an abundance of southern pine found in the region, CLT is positioned to be a growth industry in the southern U.S., benefiting the forest industry and the region’s economy.

“This was a unique opportunity and one-of-a-kind event where you had forestry and wood product professionals and manufacturers, landowners, architects, engineers, contractors, insurance professionals, economic development professionals and educators in the same space,” said Adam Maggard, conference coordinator, extension specialist and associate professor of forest systems management. “The value of this kind of opportunity to learn, network and work together to advance CLT and mass timber products and their use cannot be overstated.”

Scott Enebak, associate dean and professor in the college, commenced the session with welcoming remarks and introduced James W. Rane, Auburn trustee and the founder and CEO of Great Southern Wood Preserving Inc., one of the leading producers of pressure-treated lumber in the U.S.

With over 23 million acres of forestland in Alabama, the timber industry is a pillar in the state.

“We’ve got the land, we’ve got the timber, we’ve got the broader forest industry that puts these pieces together into a strong economic force and a value-added supply chain across the region and country, and that includes the manufacturing sector that is one of the most important industries for rural communities,” Rane said during his opening remarks. “The forest industry is the largest capital investor in many counties in our state and the largest employer throughout much of rural Alabama and across our region.”

Following Rane’s remarks, Jeff Peters, southeast regional director of WoodWorks Wood Products Council, began his keynote address by asking the audience, “What’s your Why?” As regional director, Peters provides free technical support to developers and design/construction teams working on commercial or multi-family wood buildings.

“In terms of advancing cross-laminated timber here in the South, I really think it’s a massive education gap,” said Peters during a recent interview. “So, one of the things that we are doing at WoodWorks is trying to break down those barriers by increasing design teams, contractors and developers’ knowledge on mass timber.”

The conference design and theme centered on the CLT supply chain. Plenary sessions explored diverse topics, including current and future implications for forest management, the wood products sector, mass timber markets and economies.

Later in the conference, attendees chose from two concurrent session tracks with experts who addressed various topics related to CLT manufacturing, supply chain, engineering, design and construction and other factors influencing the use and advancement of CLT in the South.

An expert panel discussion, led by Peters, delved into answering numerous questions surrounding CLT.

Peters noted that the question of CLT cost arises frequently, and that the conference panel discussion provided the opportunity to explore this in more depth.

“It was great to have the diverse industry expertise of Derek Ratchford of Smartlam North America and Jeff Morrow of Timberlab Inc. to weigh in on this topic,” said Peters. “Currently, cost really depends on the complexity of the structure; it depends on the fire-resistance rating and the construction type; and it depends on multiple other factors. We have decades of historical data in terms of cost when it comes to pricing a steel or concrete structure, but very little in comparison to a mass timber building.”

More information about the conference’s speakers is available online.

Showcasing current research related to the advancement of mass timber, undergraduate and graduate students presented their research on diverse topics, from predicting the carbon content in wood samples to the use of fiber from reclaimed loblolly pine downed timber to the use of renewable polymers for CLT protection coatings.

During the conference’s final day, attendees took part in tours that showcased CLT manufacturing and construction in Alabama. One tour visited the SmartLam North America CLT manufacturing plant in Dothan, Alabama, where participants learned how CLT is engineered and prefabricated to a building project’s exact specifications and requirements.

Another tour visited Auburn’s recently completed 41,500-square-foot Advanced Structural Engineering Lab to learn about CLT structural testing research. Partially designed using CLT, this laboratory features a 4,700-cubic-foot geotechnical test chamber and a wind testing facility.

Following the lab, the local tour continued to the Hey Day Market that is currently under construction at the Tony and Libba Rane Culinary Science Center at Auburn. The 9,000-square-foot building, which will house a dining hall and business center, is being constructed with CLT and glue-laminated timber, or GLT.

“This conference reflects the significance of CLT and other mass timber products to stakeholders and the growing demand for sustainable building alternatives and advancement of innovative wood products,” said Janaki Alavalapati, the college’s dean. “The economic impact of CLT and other mass timber products across multiple industries in Alabama, the region, nation and beyond is growing exponentially, and the synergy this conference provided was needed to advance CLT.”

Attendees said the conference exceeded their expectations.

“I really enjoyed having several people from different ends of the industry attending. The discussions from supply to design to construction added to the knowledge and understanding of the segment,” noted one attendee in a survey.

The College of Forestry, Wildlife and Environment partnered with the College of Architecture, Design and Construction, the Samuel Ginn College of Engineering, the Office of Sustainability and the Office of the University Architect to host the event.

To view photos and video from the conference, visit Flickr.com and YouTube.

(Written by Gracen Carter)

Conference sponsors:

Platinum

Made in Alabama

SmartLam North America

Gold

Alabama Power

Forest Landowners

The Forest Landowner Foundation

Western Wood Structures

Westervelt Company

Silver

Alfa Farmers Federation

Rayonier

Southeastern Land Group

Bronze

Simpson Strong Tie

Vapro Shield

Wood Products Council

Related Media

Media interested in this story can contact Communications Director Preston Sparks at (334) 844-9999 or preston.sparks@auburn.edu.

The Auburn University College of Forestry, Wildlife and Environment is a flagship institution for natural resources-based degrees including natural resource management, geospatial and environmental informatics and sustainable biomaterials and packaging. The school serves as the backbone for Alabama’s $30 billion+ forest, wildlife and natural resources related enterprises. Its mission is to create next-generation professionals and leaders, to develop new knowledge and disseminate science-based solutions to our clientele to improve the social, economic and environmental well-being of citizens in Alabama and beyond.